DEVELOPED BY EVANS ENGINEERED PRODUCTS

LOWER COST AND FASTER TURN-AROUND time than traditional silicone

Our GREENSTRIP KEDER offers all of the mechanical properties required for silicone edge graphics at a lower cost and faster turn-around time than traditional silicone. The Evans lubricant package for GreenStrip has quickly become the product of choice over talc-coated silicone as it is less messy and helps lubricate both sewing machine feed chutes as well as the actual sewing needles.

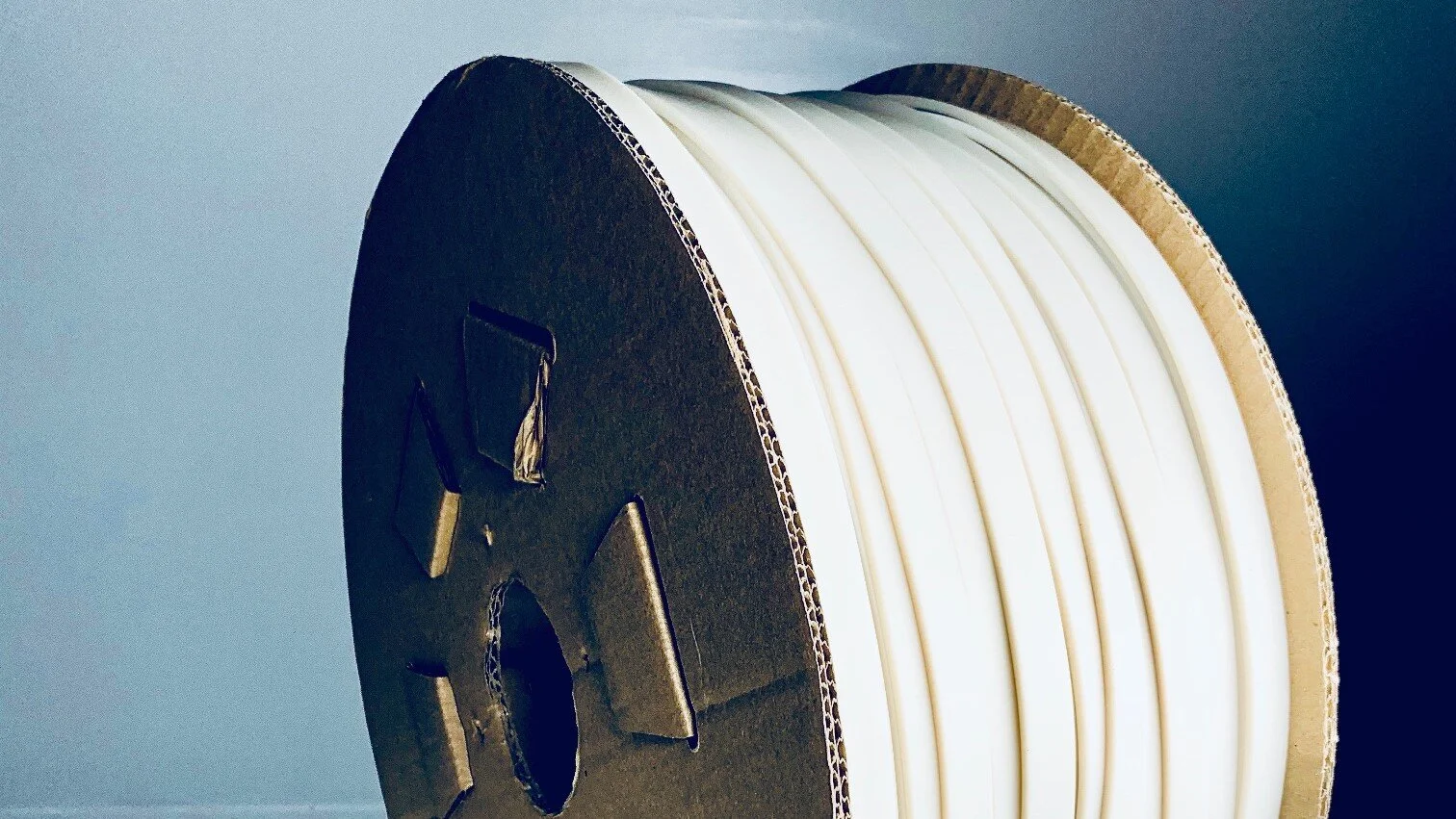

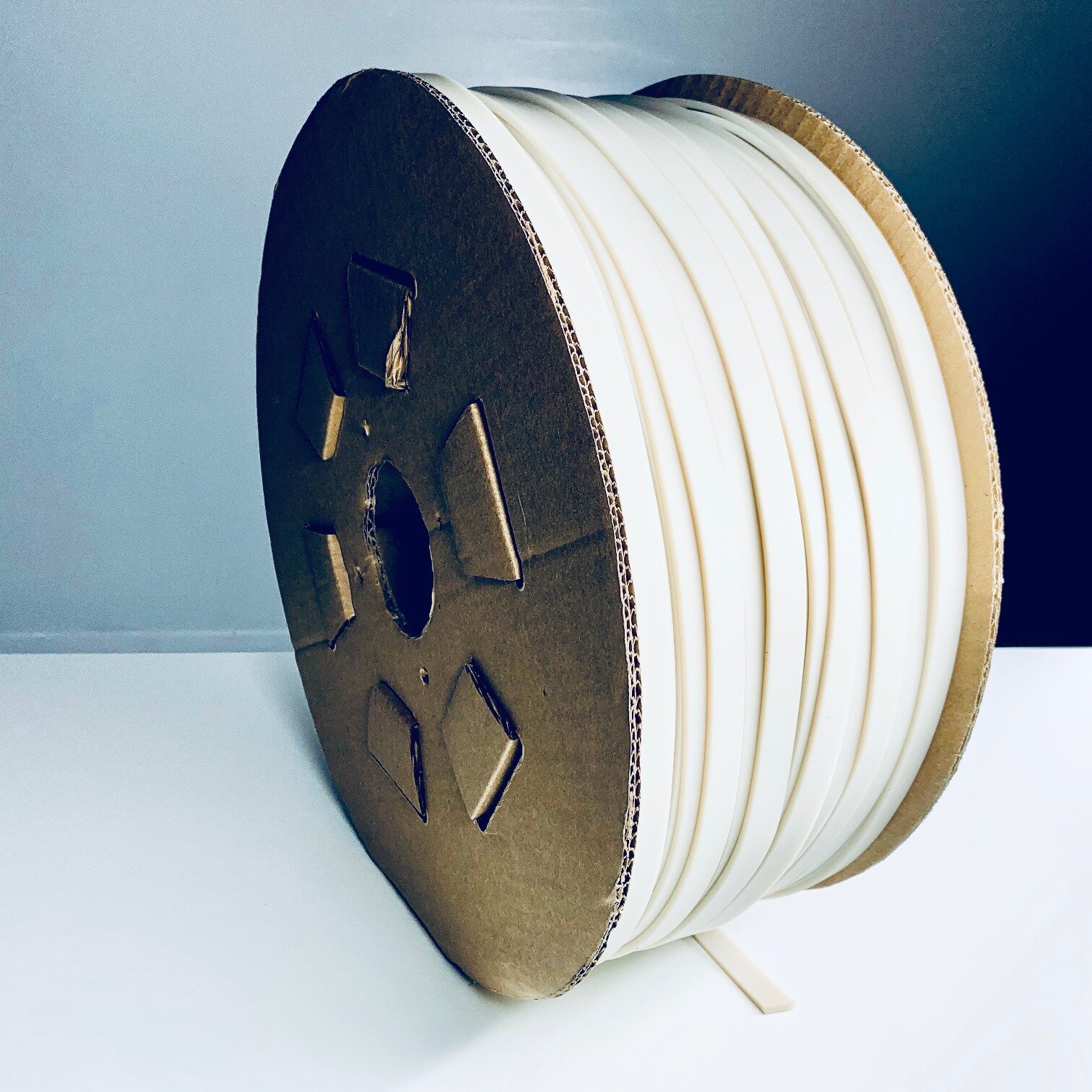

THERMOPLASTIC allows for high speed production

GREENSTRIP is a thermoplastic which means there is no curing stage during production – raw materials are simply heated to a specific temperature, pressurized, shaped into the desired keder size, and then cooled before packaging. This allows for high speed production with minimal plant floor space. Evans Engineered Products has also designed its own custom packaging equipment to neatly spool our GREENSTRIP keder while keeping it free of dirt and contaminants.

CUSTOM SIZES ready in 24 hours

The most common sizes of GREENSTRIP are stocked at our warehouse and available for immediate shipment. We also offer fast delivery of custom sizes to meet any application requirements. Turnaround time on a custom size can be as fast as 24 hours. This means customers can have the perfect fit for their applications in the tight time frames that are often required to win big jobs.

GREENSTRIP can be recycled indefinitely

GREENSTRIP can be recycled in traditional recycling chains that handle polypropylene (PP) -based products. and can be recycled indefinitely with virtually no reduction in mechanical properties.

TESTIMONIAL

““GREENSTRIP keder from Evans Engineered Products has been our go-to keder product ever since we started using it. Its quality and availability are second only to the awesome people at Evans who make it :)””